Whether it is manually rebuilt RBA or our common finished atomizer, in fact, the phenomenon of oil frying is common, especially the newcomers who have just been exposed to e-cigarettes are even more annoyed. Today, we have five questions about frying oil. And processing methods, I hope to provide you with some reference and help.

What is the atomizer frying oil?

First of all, confirm what is the phenomenon of “fried oil”… We all know that more than 90% of the atomizing cores in the electronic cigarette atomizer use the structure of cotton to carry the smoke oil, and the physics of the smoke oil becomes water mist by the coil heating. reaction. In the rapid temperature rise of the coil, it is often caused by various reasons that the smoke oil is not directly generated by the water mist, but the smoke oil is directly injected out of the coil and even into our mouth. This is the phenomenon of frying oil that we often say.

What is the biggest factor that causes the oil to be fried?

Cotton is actually the biggest influencing factor! In the center of the atomizing core coil, we often say that the “full” state is the most perfect, then the most visual test for this “full” is the frying oil. If the amount of cotton is too large, the cotton in the c enter of the coil is too tight, which will lead to the reduction of the taste of the smoked oil, that is to say, the amount of smoke used in a single atomization is reduced; if the amount of cotton is too small, the coil will be caused. The amount of smoke oil in China’s cotton is excessive. When the coil heats up rapidly, it often appears that the smoke oil will fly directly in the form of liquid!

1、[power] Improper use of power will cause the frying oil, for example, the power is too low, the heating speed of the coil is too slow, the coil will fry the smoke before reaching the atomization temperature.

2、[smoke oil] The VG content of the smoke oil used should be in accordance with the oil guide setting of the core. Some of the finished cores are positioned with large smoke and have extremely fast oil guiding design. At this time, the use of VG is too low (50%) of the oil will lead to excessive oil, which is the excessive amount of cotton smoke oil mentioned above. oil

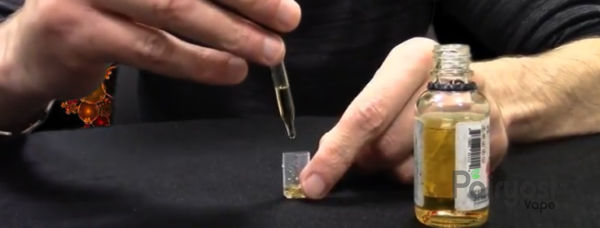

3、 [Run core] In the process of running the core, if the smoke oil is injected too much, there will be fried oil. Most of the newly used finished cores will be run by the core, and too much wetting of the core will result in excess fumes, which will inevitably appear in the first and second mouths. In most cases, it has nothing to do with the quality of the core.

What factors affect cotton oil besides cotton?

Aside from the excess of smoke caused by the amount of cotton, it is possible that another major cause of the oil is the output power of the main engine. As mentioned earlier, the frying oil is actually the smoke oil on the cotton being blown up instantaneously, then the power output of the main engine becomes the biggest influencing factor. If the output of the host is unreasonable, even if the fried oil does not exist, it will affect the taste reduction of the smoked oil. Reasonable output is the basis for a good experience of the electronic cigarette.

But in fact, in addition to these important factors, the structural part of the atomizer is also constantly optimized to prevent the frying oil. For example, some RTAs use anti-frying oil nets and other designs, which can also show significant improvement in preventing oil. If you still have your own unique insights into the fried oil, you are welcome to speak freely under the article…